Production of Our Lithium Iron Phosphate

For more than 10 years IBU-tec has been involved in the development and production of LFP cathode material. The starting materials first pass through spray drying, are refined in a rotary kiln and then milled: an excellent production performance with high quality.

LFP in Different Particle Size Distributions

IBUvolt® LFP is offered in two variants - LFP400 and LFP402. LFP400 is a coarser form of LFP powder (d50 ~11 µm) with good volumetric energy density (Wh/L), very good specific power (W/g) and excellent cycle life. LFP400 has been successfully tested for use in stationary storage systems and is particularly suitable for aqueous or dry coating. LFP402 is a finer form (d50 ~1 µm ) of LFP with a very high specific discharge capacity (mAh/g) and optimized compactability. This variant can be easily processed on established production systems and is therefore suitable for both electromobility and stationary storage applications.

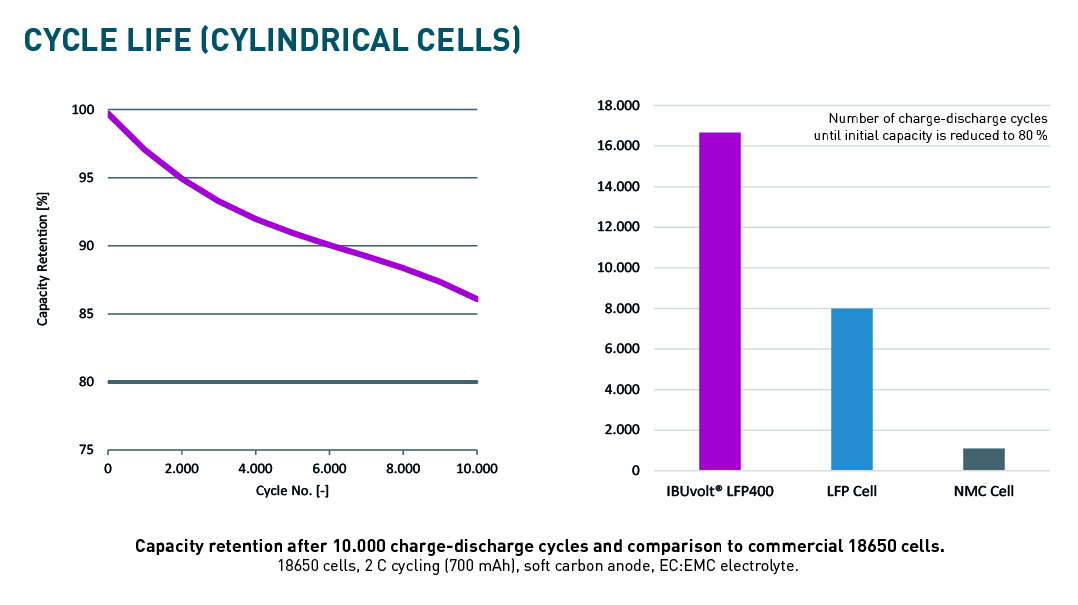

IBUvolt® LFP400 – Long Life and Cycle Stability

IBUvolt® LFP retains its capacity over thousands of charging cycles – a comparatively long service life. This means that the specific costs per charge cycle or kilometer are reduced by up to 50 % for a comparable acquisition cost due to a significantly longer operating time. IBUvolt® LFP 400 has been successfully tested over 10,000 charge/discharge cycles at a discharge rate of 2C in the 18650 cylindrical cell format, which corresponds to a service life of over 15 years.

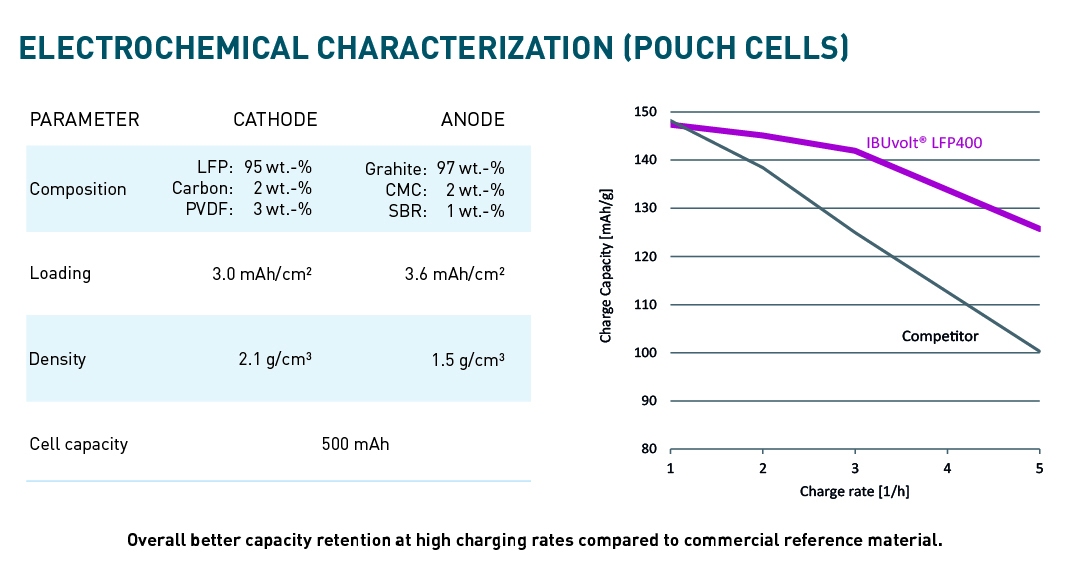

Electrochemical Properties

The comparatively high carbon content of IBUvolt® LFP 400 of 3.5 - 3.9 % by weight leads to the advantage of high electrical conductivity. This reduces the internal resistance in the battery cell and less electrical energy is converted into heat. This increases energy efficiency and safety compared to other LFP products with lower conductivity. Furthermore, the high carbon content of IBUvolt® LFP makes it possible to use less conductive carbon black in cathode production, which means savings in cell production costs.

IBUvolt® LFP402 – Small Particles Enable High Energy Densities

IBUvolt® LFP402 was developed to meet the requirements of global cell manufacturers. The product offers good processability in the production of battery cells on an industrial scale. The cathode material has a high specific capacity of > 159 mAh/g, high compactability and very good conductivity.

Compacting Properties

IBUvolt® LFP 402 has been optimized with regard to a low carbon content of 1.4 % by weight. This results in improved compactability and conductivity of the material. At a pressure of 3 tons, LFP402 can be compacted to 2.4 g/cm³ with a high conductivity of ~40 mS/cm. These properties also increase the energy efficiency and safety of electrodes and cells made from this material.

Background on Lithium Iron Phosphate Batteries

Energy storage systems are a valuable key technology for not having to rely on the use of fossil raw materials for energy production and being able to use other sources, such as wind power and photovoltaic systems. Currently available storage systems are largely based on the proven lithium-ion battery technology. Lithium-ion batteries consist of four basic components that make up the battery's cells: Cathode, Anode, Separator and Electrolyte. IBU-tec has many years of experience in the production of lithium iron phosphate cathode material (LFP or LiFePO4).

When charging a lithium-ion battery or lithium-ion accumulators, lithium ions are transported through the electrolyte layer from the cathode to the anode. In the anode, which is often made of graphite or other carbon-rich materials, the reversible intercalation of the lithium takes place with the absorption of electrons. When the battery is discharged, this process is reversed. The lithium-rich anode layer releases electrons and the resulting lithium ions are transported to the cathode. The resulting current flow can be used by electrical consumers. This cycle can be repeated several times in rechargeable batteries, although certain memory effects are inevitable. The higher the quality of the battery and the materials used in it, such as lithium iron phosphate, the longer the service life can be.

Lithium iron phosphate is becoming increasingly important as a cathode material in modern batteries. Depending on the end application and field of use – be it in the field of e-mobility or in stationary energy storage – different requirements arise.

The designation LFP is derived from the empirical formula LiFePO4. LFP cathodes are free of the heavy metal nickel and the critical raw material cobalt. Compared to other cathode materials, LFP also shows advantages in durability and safety.