Spray Dryer Operating Principle

Spray drying is a continuous thermal drying process for the production of powders from solutions, suspensions or emulsions. The liquid is sprayed with an atomizer, in our case a dual-substance nozzle: finely distributed liquid droplets are produced, which are dried in a hot gas stream. Due to the extremely high surface area of the spray mist, efficient drying with low energy consumption is possible. The hot gas flow required for this can be generated by various methods, such as an electric cartridge heater. Ambient air is usually drawn in as the drying gas; alternatively, pre-dried air or nitrogen can be supplied. Separation of the product after thermal treatment is usually by two-point or single-point discharge in a cyclone or through a filter. The product properties can be influenced by the physicochemical properties of the sprayed material as well as by the nozzle setting, the temperature, the volume flow, the throughput or by the design of the system.

IBU-tec Laboratory Spray Dryer

Our Gea Mobile Minor type MM laboratory spray dryer is particularly suitable for product development: Small quantities of feedstock are dried into representative samples and the process data required for scale-up to industrial production is generated. The flexible design of the spray dryer allows us to meet a wide range of requirements.

Configuration Options

In the run-up to your project, we customize the configuration of the spray dryer; two variants are typical: a direct current method and a mixing method. The tower can also be operated at two different heights, i.e. with two different residence times due to its design. The hot gas flow can be individually influenced in the tower with the aid of a specially developed component: The hot gas can flow into the tower centrally, coaxially or over a wide area.

Single-substance and dual-substance nozzles in various sizes are available as atomizers; for particle separation, you can choose between a two-point discharge (coarse fraction at the tower and fine fraction in the separator) and a single-point discharge with separator (e.g. cyclone and/or filter).

Facts & Data

- Plant scaling: approx. 2.5 m x 2 m x 2.5 m

- Maximum operating temperature: 350 °C

- Drying capacity: 0.5 - 5 kg/h water evaporation

- Hot gas flow: up to 100 kg/h

- Typical average particle size: 5 - 80 µm

- Spray liquids: solutions, suspensions and emulsions

- Reaction control: continuous direct current or mixed process

- Heating gas types: ambient air, pre-dried air, nitrogen

- Typical processes: Drying, agglomerating, granulating

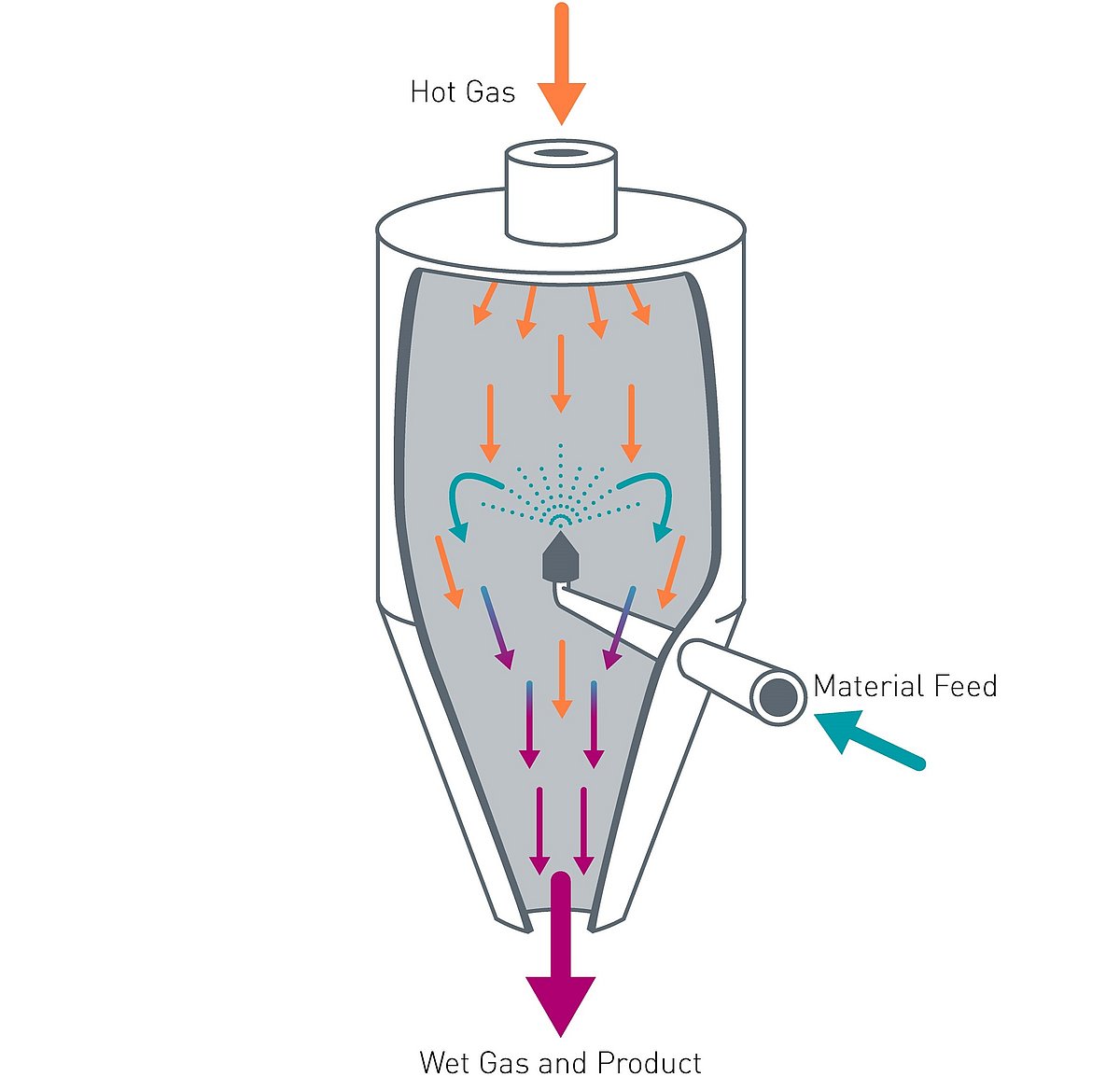

Co-Current Process

For the co-current process, hot gas is introduced in the direction of the sprayed material. The particles therefore move in the same direction as the hot gas. The particles with the highest moisture content also experience the highest temperatures. The direct current process (top-down process) thus dries the material particularly gently and is suitable for the production of fine and temperature-sensitive powders.

Mixed Flow Mode

In the mixed flow mode, countercurrent and co-current are combined, so that the material to be sprayed is fed into the spray tower from below, while the hot gas flows downwards from above. The particles follow a trajectory similar to a fountain – hence the informal name "fountain process". The product is still discharged at the conical bottom of the tower. This configuration is particularly suitable for producing larger particles and is more energy efficient.