Thermal-Shock Calcination

The operational principle of a pulsation reactor is to expose a material to a hot gas for a very short time. To ensure that all of the material reacts with the gas to the same extent, it needs to be dispersed in the gas very homogeneously. To control the reaction time, the reaction then has to be stopped and the material separated from the gas very quickly.

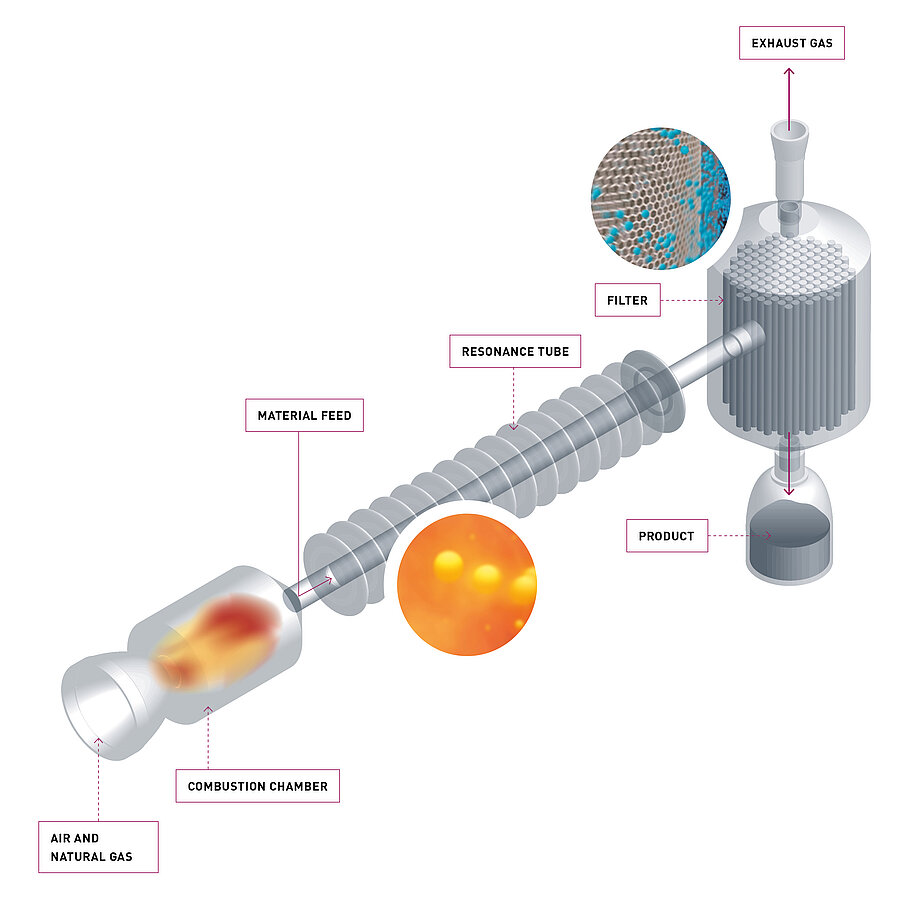

To achieve this treatment, a pulsation reactor has a simple but effective construction consisting of a combustion chamber with a natural gas burner, a resonance tube and a product filter. In the combustion chamber, the burner generates a periodic transient stream of hot gas. The gas passes into the resonance tube in a highly turbulent flow. At the beginning of the resonance tube, the material to be treated is injected into the gas stream, and instantly becomes very evenly suspended in the gas due to the high turbulence. That's where the material treatment takes place, with a residence time of only 0.05 to 2.0 seconds. The reaction is then stopped by shock cooling (injection of cold gas).

At the end of the resonance tube, a filter separates the product from the gas stream, so it can be sorted into suitable containers. The gas pressure inside the reactor is slightly below atmospheric pressure. This means that no material is lost to the outside, ensuring a high yield rate.

Production Method for Ultrafine Powders

What makes a treatment in the pulsation reactor unique among other treatments is the extremely rapid heating and cooling of the material. In effect, it undergoes a thermal-shock calcination with extremely short residence time, in which a massive exchange of energy and matter takes place. This treatment generates characteristics in the material that can be highly advantageous for catalysts, electronics components, doping or materials with special morphological attributes.

During the treatment, IBU-tec can alter the temperature, the residence time of treatment, as well as the frequency and amplitude of the pulses. Changes in these parameters will influence the particle size, surface structure and phase composition of the target material. The resulting product is an ultrafine powder with properties that are precisely tailored for your application. High turbulence in the reactor ensures that every particle is exposed to the same reaction conditions, resulting in an exceptionally homogeneous product. These are the properties that make the pulsation reactor an appealing alternative to other calcination processes in circumstances that demand exceptionally high product quality.

A video showcasing the pulsation reactor´s operating principle is linked here.

- Pulsation Reactor

-

Characteristics and Capacities

Name

Gas atmosphere

Residence

time [s]Temperature

range [°C]Raw material

throughput

[kg/h]Special

featuresThermal

Output

[kW]Heating

typePR 10

oxidizing,

(inert)0.5 to 2

250 up to 950

up to 160

500 natural gas

PR 9

oxidizing

0.1 to 1

500 up to 950

up to 160

DeNOx

250 natural gas

PR 8

oxidizing

0.1 to 1

500 up to 950

up to 160

250 natural gas

PR 7

oxidizing

0.1 to 1

500 up to 950

up to 160

250 natural gas

PR 6*

oxidizing,

(inert)0.1 to 2

250 up to 1300

up to 80

500 natural gas

PR 5

oxidizing

0.1 to 1

500 up to 950

up to 160

250 natural gas

PR 4

oxidizing

0.1 to 1

500 up to 950

up to 80

DeNOx

150 natural gas, (H2)

KM-PR oxidizing 0.05 to 1 250 up to 1000 0.1 to 20 individually

tailored to customer

requirements50 natural gas

*limited availability

-

Downloads

Using Pulsation Reactors to Control Material Characteristics

Particle size

- The unique property of the pulsation reactor is the rapid heating and cooling rates in combination with the strong heat transfer from the hot gas to the material. This can influence the particle size when the material is introduced as a solution; enabling the formation of particles in the submicro to micrometer range.

Surface Characteristics

- The surface characteristics of the particles are influenced by the reaction temperature and the residence time. Manipulation and fine-tuning of these two parameters enables surfaces suitable for different applications.

Activity and Selectivity

- Processing in a pulsation reactor can yield materials with very fine crystallites and very narrow crystallite size distributions. These properties are key to the activity and selectivity of catalysts.

Morphology

- The pulsation reactor enables the formation of extremely small homogeneous structures in crystalline materials – forming completely new products that are especially interesting as catalysts because of their special morphology.

Homogeneity

- Throughout the cross-section of the gas flow in the reaction chamber, a nearly constant temperature profile is created by the pulsating hot gas stream. This ensures a truly homogeneous treatment. The resulting products are exceptionally homogeneous in terms of their particle size, specific surface area and phase composition.

Aggregate Formation Without Sintering

- In a solution, it is easy to achieve an ideal distribution of elements by controlling their concentrations. This is an excellent starting point for generating particulate materials with controlled elemental composition. The solution is sprayed into the reactor in very fine droplets which all contain the same proportions of elements. From the droplets, particles are generated in the form of oxides, doped oxides and mixed oxides.